>What is a profile knife

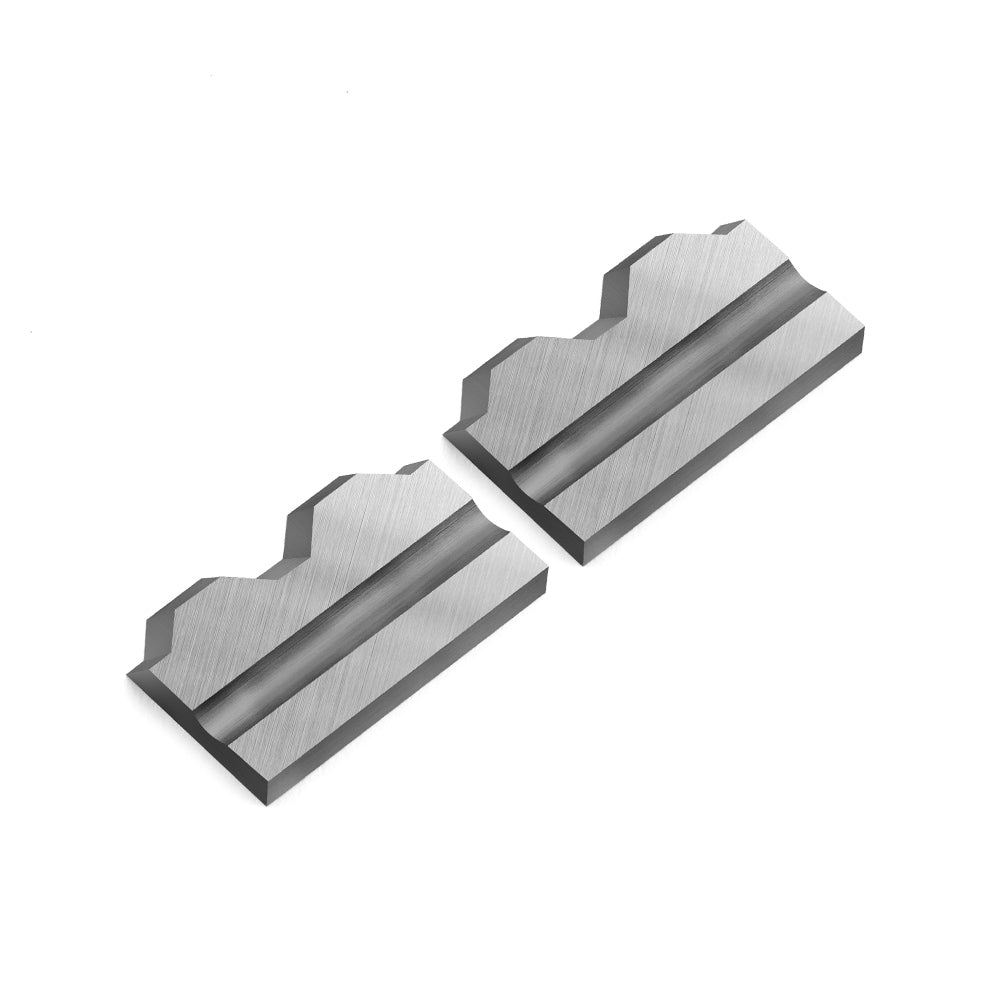

A profile knife, also known as a profiling knife or a custom knife, is a specialized cutting tool used in woodworking and other industries to shape and create specific profiles or patterns in materials such as wood, plastic, or metal. It is designed to replicate a specific shape or contour, allowing craftsmen to create intricate and precise designs with ease.

Profile knives are typically made from high-quality tool steel and are available in various shapes and sizes. They consist of a cutting edge or blade that is shaped to match the desired profile and a body or shank that fits into a corresponding cutter head or molding machine. The blade is securely attached to the shank, ensuring stability and accuracy during the cutting process.

The primary function of a profile knife is to replicate a specific profile or pattern repeatedly and consistently. These profiles can range from simple shapes such as straight edges or curves to more complex designs with intricate details and contours. Common profiles include decorative moldings, beveled edges, raised panels, and various architectural or furniture details.

Profile knives are used in a variety of industries and applications. In woodworking, they are commonly used in the production of furniture, cabinetry, millwork, and architectural components. These knives allow craftsmen to create unique and customized designs, adding aesthetic value to their work. They are also used in the production of flooring, doors, windows, and other wooden products where precise profiles are required.

In the plastic and metal industries, profile knives are used for shaping and cutting materials such as PVC, aluminum, or steel. They are often employed in the production of extruded profiles, window frames, door frames, and other structural components. Profile knives for these applications are typically made from carbide or other high-strength materials to withstand the rigors of cutting harder materials.

The process of using profile knives involves several steps. First, the desired profile is designed or chosen based on the intended application. Then, a custom profile knife is manufactured or selected to match the desired shape. The knife is installed in a suitable cutting machine or tool, such as a shaper, molder, or CNC router. The material to be shaped is then fed into the machine, and the profile knife cuts or shapes the material according to the desired design.

One of the significant advantages of using profile knives is their versatility. Craftsmen can create a wide range of profiles by simply changing the knife in the cutting tool. This flexibility allows for quick and efficient production of different designs without the need for specialized machinery or additional setup time. It also enables the customization of profiles to meet specific project requirements or to match existing architectural styles.

Furthermore, profile knives offer excellent precision and repeatability. Once a profile is established, craftsmen can reproduce it accurately and consistently, ensuring uniformity across multiple pieces or components. This level of precision is crucial in industries that require standardized production or when matching existing profiles is necessary.

In conclusion, profile knives are specialized cutting tools used in woodworking, plastic, and metal industries to shape and create specific profiles or patterns. They offer versatility, precision, and repeatability, allowing craftsmen to produce intricate and customized designs with ease. Whether it's creating decorative moldings, architectural components, or extruded profiles, profile knives play a vital role in the manufacturing of various products.